Collision repair adhesives have revolutionized modern auto body repair, offering precise and efficient bonding solutions for various repair stages. They replace traditional methods, speed up repair cycles, protect surrounding components, maintain structural integrity, enhance quality, and reduce costs. These adhesives are crucial for achieving top-tier repairs, especially on luxury vehicles like Mercedes Benz. However, proper application techniques and material compatibility are essential; eco-friendly options also address sustainability concerns.

Collision repair adhesives play a pivotal role in modern automotive body shop processes, offering precision and efficiency. This article explores the integration of these specialized products into contemporary collision repair, highlighting their significance alongside understanding the dynamic nature of the industry. We’ll delve into how adhesives facilitate faster, more durable repairs, while examining the advantages and challenges associated with their implementation. From enhanced structural integrity to streamlined work flows, collision repair adhesives are transforming the way we restore vehicles.

- Understanding Modern Collision Repair Processes

- Role of Collision Repair Adhesives in Repair

- Advantages and Challenges of Using Adhesives

Understanding Modern Collision Repair Processes

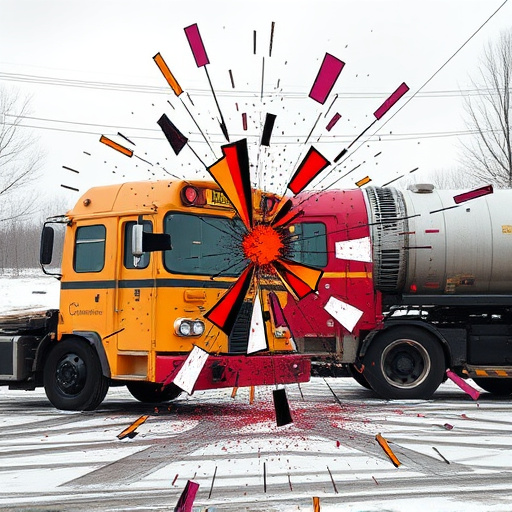

Modern collision repair processes have evolved significantly over the years, driven by advancements in technology and a focus on efficiency and quality. These processes encompass a range of activities from initial assessment and estimation to complex structural repairs and refinishing. The integration of collision repair adhesives has been a game-changer in this landscape. Adhesives now play a pivotal role in various stages of restoration, offering precise bonding solutions for everything from fender benders to extensive car scratch repairs.

Automotive restoration, once reliant on traditional fastening methods like riveting and welding, benefits from the precision and efficiency of adhesives. They enable faster repair cycles, minimize damage to surrounding components, and provide structural integrity for a seamless finish. This not only enhances the overall quality of the repair but also reduces costs associated with labor and material wastage, making collision repair more accessible and cost-effective for both repair facilities and vehicle owners.

Role of Collision Repair Adhesives in Repair

Collision repair adhesives play a pivotal role in modern collision repair processes, revolutionizing how auto body services address damage to vehicles. These specialized adhesives are integral to repairing various components, from metal panels to intricate interior parts, ensuring seamless integration and strength. In the realm of car body shops, where precision and efficiency are paramount, collision repair adhesives offer a game-changer.

They enable technicians to precisely mend cracks, dents, and other impairments, restoring vehicles to their pre-accident condition. For instance, in a Mercedes Benz repair, collision repair adhesives facilitate the meticulous restoration of panels, maintaining the car’s original aesthetics. This advanced adhesive technology not only enhances structural integrity but also contributes to the overall quality and longevity of auto body repairs, making them an indispensable tool in contemporary collision repair practices.

Advantages and Challenges of Using Adhesives

Collision repair adhesives play a pivotal role in modern collision repair processes, offering several advantages that enhance efficiency and quality. One of the primary benefits is their ability to provide strong bonds, often surpassing the strength of the original car bodywork. This ensures structural integrity during repairs, leading to more durable and safer cars. Adhesives also streamline the repair process by reducing the time required for welding or riveting, thereby minimizing downtime for both customers and auto body shops.

However, despite these advantages, there are challenges associated with using collision repair adhesives. One significant hurdle is ensuring proper application, as incorrect usage can lead to weak bonds or unsightly finishes. Moreover, not all adhesives are compatible with every type of car bodywork material, necessitating precise matching for optimal results. Additionally, the environmental impact of adhesives must be considered, with many modern formulations aiming to reduce their ecological footprint while maintaining performance standards in car body repair.

Collision repair adhesives play a pivotal role in modern collision repair processes, offering both efficiency and durability. By understanding their application and benefits, shops can enhance their operations, resulting in higher-quality repairs and improved customer satisfaction. Despite challenges, the advantages of using specialized adhesives make them an indispensable tool for staying ahead in the industry. Incorporating these innovative solutions into workflows ensures that collision centers keep pace with modern automotive demands.