Collision repair adhesives are essential for restoring damaged cars, offering unique properties for various repairs. Safe handling is critical, requiring protective gear and proper ventilation to mitigate health risks and structural weaknesses. A structured protocol includes equipment use, surface preparation, precise application, gentle bonding, curing per instructions, and careful tool removal, ensuring secure bonds and safe car restoration.

In the realm of collision repair, understanding the intricacies of handling adhesives is paramount. Collision repair adhesives play a crucial role in ensuring structural integrity and quality finishes. However, their use comes with inherent risks, from health hazards to potential environmental impact. This article delves into the essential safety protocols required for handling collision repair adhesives, equipping professionals with the knowledge to mitigate risks effectively. From understanding adhesive properties and identifying associated dangers to equipping oneself with proper safety gear and implementing secure application and removal processes, this guide covers it all.

- Understanding Collision Repair Adhesives: Properties and Risks

- Essential Safety Gear for Adhesive Handling

- Step-by-Step Protocol for Secure Application and Removal

Understanding Collision Repair Adhesives: Properties and Risks

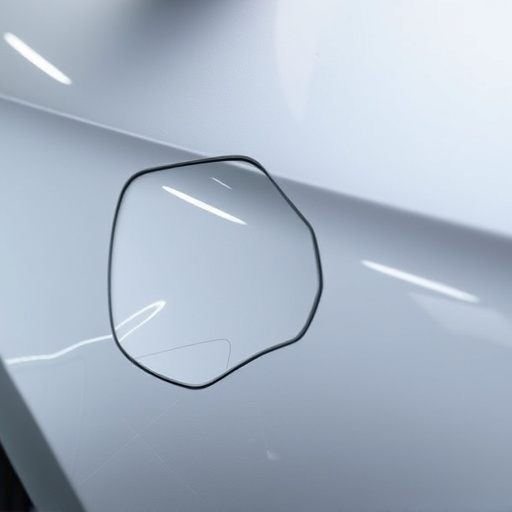

Collision repair adhesives play a critical role in the car body shop, serving as the bond that restores damaged cars to their original state, whether it’s mending car dent repair or fixing intricate car scratch repairs. These adhesives are designed with specific properties to ensure structural integrity and long-lasting durability. However, understanding these adhesive solutions is crucial due to potential risks associated with their application.

The diverse range of collision repair adhesives comes with varying compositions, each offering unique advantages. Some are formulated for high-strength bonding, ideal for major car body repairs, while others cater to more precise applications in car scratch repair. Despite their benefits, these adhesives pose risks if not handled properly. Health concerns, such as respiratory issues and skin irritation, are common hazards, highlighting the need for adequate ventilation during application. Moreover, improper use can lead to structural weaknesses or even failed repairs, emphasizing the importance of adhering to safety protocols in car dent repair and other collision repair procedures.

Essential Safety Gear for Adhesive Handling

When it comes to handling collision repair adhesives, safety should never be compromised. Professionals involved in luxury vehicle repair or any car paint repair process must don appropriate protective gear. This includes respirators or masks to filter out harmful fumes, as many adhesives can release toxic vapours during application. Safety goggles are also non-negotiable, shielding the eyes from potential splashes or debris that may result from the mixing and application of these substances.

Gloves and long-sleeved garments are essential to protect the skin from direct contact with the adhesive, which can cause irritation or chemical burns. In addition, a lab coat or apron provides a barrier against any accidental spills or splatters, especially during dent removal procedures where adhesives may be used extensively. Ensuring that all safety gear is worn correctly and consistently minimises risks associated with collision repair adhesives.

Step-by-Step Protocol for Secure Application and Removal

When handling collision repair adhesives, a structured protocol is paramount to ensure safety and effective application. Begin by donning appropriate personal protective equipment (PPE), including gloves, safety goggles, and a respirator mask to shield against chemical fumes. Ensure your work area is well-ventilated or use an exhaust fan to maintain optimal air quality. Next, thoroughly clean the surface to be bonded, removing any debris, grease, or previous adhesive residue using appropriate solvents as recommended by the manufacturer.

Proceed with a dry fit of the components to be joined, ensuring proper alignment and fit. Apply a thin layer of collision repair adhesive along the bonding interface, following the manufacturer’s instructions for ideal application techniques specific to different types of adhesives. Gently press the parts together, creating a strong bond. For precise results in fender repair or automotive restoration projects, maintain even pressure across the joint line. After a cure time as specified by the adhesive manufacturer, carefully remove any excess material using a sharp blade or scraper designed for adhesive removal. This meticulous process ensures a secure bond without unwanted residue, readying the surface for subsequent steps in tire services or other repair procedures.

Collision repair adhesives are essential tools in the automotive industry, but their handling requires stringent safety protocols. By understanding the unique properties and risks associated with these adhesives, along with wearing appropriate safety gear, professionals can ensure a secure work environment. Following a structured protocol for application and removal not only enhances efficiency but also minimizes exposure to harmful substances. Adhering to these guidelines is crucial for the well-being of repair technicians and the quality of collision repair work.